There are several types of polyethylene film, each with a different density and use. Polyethylene tape is categorized by the tape’s density:

vulcanizing tape. The tape will adhere to itself and create a tight, secure bond that is resistant to moisture and corrosion.

Despite its thin width, 3mm electrical tape is durable and resistant to wear and tear. It can withstand high temperatures, moisture, and UV exposure without deteriorating or losing its adhesive properties. This makes it a reliable choice for both indoor and outdoor applications, where weather and environmental conditions may vary.

Durability and longevity: Silicone rubber tapes offer excellent longevity and toughness, making them a reliable choice for long-term repairs. Rubber repair tapes, on the other hand, offer durability and flexibility, making them ideal for a variety of repair tasks.

Self-Fusing Silicone Electrical Tape A Versatile Solution for Electrical Insulation

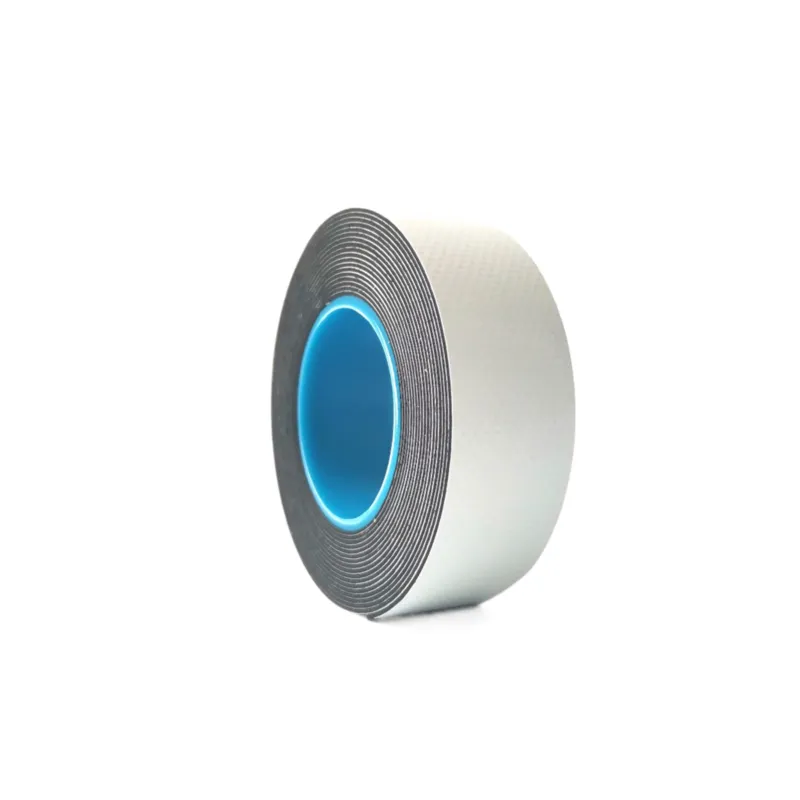

Polyethylene Rubber Tape has several important characteristics:

In the realm of electrical engineering, high voltage systems require robust solutions to ensure safety and efficiency. One of the critical components in the insulation of high voltage busbars is the insulation tape. This tape plays a vital role in preventing electrical failures, protecting equipment, and ensuring safe operational environments.